1. Tsebisa ho romelloa ha motlakase, 'me ramotlakase o tla sebetsana le mekhoa ea ho tima motlakase;

2. Netefatsa hore phepelo ea motlakase ea crusher e khaotsoe, 'me u tšoaee boemo ba tlhokomelo ea lebokose la ts'ebetso' me u fanyehe karete ea tlhokomelo ka nepo;

3, pheko ea khatello ea pompo ea lubrication;

4. Hula sesebelisoa sa ropo bakeng sa lebanta la morafo 'me u hloekise pumice hloohong ea lebanta;

5. Tlosa likotoana tse 'nè tse kholo, tse kang sekoahelo sa ho phahamisa, cauldron, sekoahelo sa sekoahelo le sekoahelo sa lerōle le tsitsitseng.Nakong ea ts'ebetso ea ho phahamisa, crane e tla laeloa ke basebetsi ba khethehileng' me e boloke ka tieo melao ea ts'ebetso ea ho phahamisa;

6, poleiti e arohaneng: hloekisa slag holim'a li-bolts tsa poleiti, tlosa bolt ea ho notlela, tlosa poleiti ho hlahloba hore na e ka tsoela pele ho e sebelisa, haeba e hloka ho nkeloa sebaka, hang-hang fumana poleiti e ncha. sledge hamore, letsoho le tšoereng hamore le ke ke la apara liatlana le ho roala likhalase, 'me ho na le basebetsi ba leihlo;

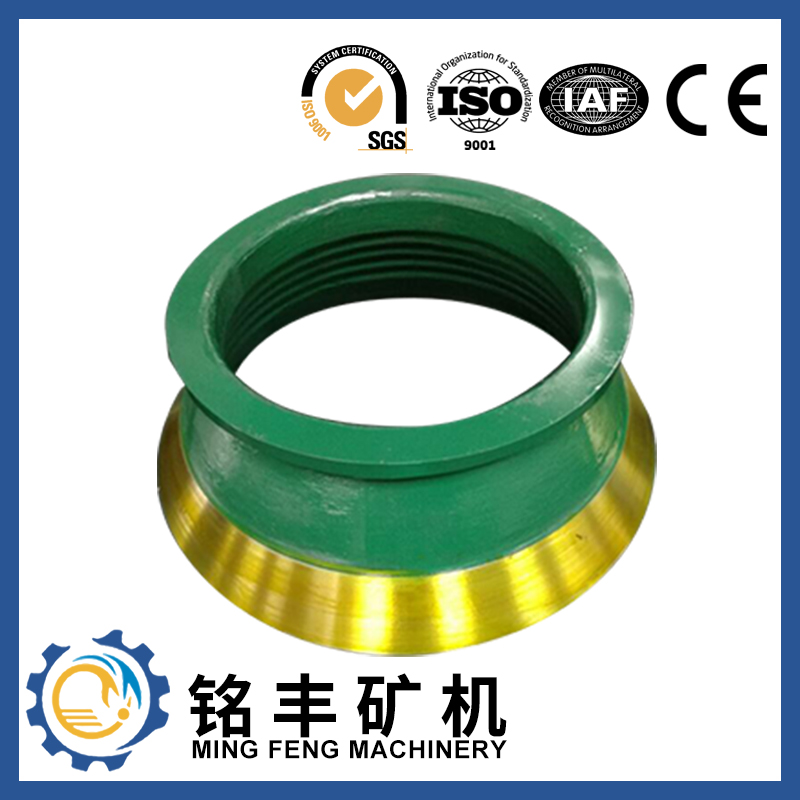

7, tlosa sekontiri se tsitsitseng: hlahloba boholo ba lisebelisoa tsa lesela (lebili) le koala, qala motlakase oa hydraulic ho potoloha lisebelisoa tsa lesale. Ts'ebetso ena e tlameha ho laoloa ke motho ea khethehileng. phahamisetswa sebakeng se kgethilweng;

8, ho qhaqha khoune ea ho phahamisa: ts'ebetso e lokela ho laoloa ke motho ea khethehileng, ts'ebetso ea ho phahamisa e lokela ho lieha le ho tsitsisa, e le ho thibela tšenyo ea ho tsamaisa koporo ea koporo;

9, hlahloba counterweight, base plate, bearing bush, rapameng (plate) le likarolo tse amanang le tsona; Haeba likarolo tse ka holimo li hloka ho nkeloa sebaka le ho hlokomeloa, li lokela ho tlalehoa ho moetapele hang-hang bakeng sa ts'ebetso e nepahetseng;

10, ho phahamisa khoune e ncha: e lokela ho lumellana le litlhoko tsa mehele e jereng le thapo ea terata, e hlakole ka hloko matheba a motso oa cone axis, ho phahamisa ho lokela ho lieha ha ho behoa holim'a sefate sa eccentric, le mooki ea khethehileng a laela, ho tsamaisa khoune le the eccentric shaft e kopantsoe 'me e lokela ho khaotsa ho oela ha e sa be teng ka botlalo, nako ena e lokela ho ba sehokelo ho hlophisa pompo ea lubrication e bulehileng 1 ~ metsotso e 2, ebe e oela khoune e tsamaeang sebakeng;

11. Ho phahamisa khoune e ncha e tsitsitseng: mokhoa oa ho beha o tlameha ho fokotseha butle butle, hlahloba ka hloko hore na sekontiri se tsitsitseng le slotte sa gear se tsamaisana hantle, le hore na ntlha ea ho qala ea khoele e tsitsitseng e lumellana le sebaka sa ho qala sa matrix. khoele.Haeba lintlha tse ka holimo li tsitsitse, qala motlakase oa hydraulic 'me u potolose sekontiri se tsitsitseng ho ea koung ea ho ntša ho finyella tlhokahalo ea tlhahiso.Ts'ebetso ena e boetse e hloka tlhokomelo e khethehileng, hlahloba boholo ba tekanyo ea gear e bapisang;

12, ho hlongoa poleiti ea ho fepa: ho tsamaisana le pini ka har'a sekoti se tsamaisang sekoti se tšehali ka har'a sekoti, bolt ea ho notlela, tšebeliso ea lintlha tsa sledgehammer tse nang le sehlooho sa 6;

13. Koahela bolt ea ho notlela ea terei ea thepa ka lesela 'me ue tlatse ka ore e sithabetseng bakeng sa disassembly e latelang;

14. Hoisting fixed cone lerōle sekoahelo, sekoahelo poleiti, pitsa e khōlō, ho fepa molomo sekoahelo se sireletsang le likotoana tse ling tse 'nè tse khōlō.theProcess notes ba tšoana le sehlooho se reng 5;

15. Khutlisa valve ea khatello ea pompo ea lubrication 'me u hlahlobe hore na khatello e finyella litlhoko tsa tlhahiso;

16. Seta hape thapo e hulang lebanta, tlosa karete ea ho ntlafatsa, fetola lebokose la ts'ebetso sebakeng sa othomathike, 'me u hloekise sebaka ka lisebelisoa;

17. Ka mor'a hore litaba tse ka holimo li sebetsanoe, tsebisa ho romelloa ho matlafatsa mochine o senyang.

Nako ea poso: Jan-11-2022