Likarolo tsa ho roala lirolara tse phahameng tsa chrome

Kakaretso:

| Mofuta | letlapa la meno, letlalo la Double Roller Crusherroller, letlalo le phahameng la tšepe la manganese | ||

| Tšimoloho | China | Khoutu ea HS | 84749000 |

| Boemo | E ncha | Liindasteri tse sebetsang | Matla le Morafo |

| Mofuta oa Mochini | Roller Crusher | Setifikeiti | ISO 9001:2008 |

| Ho thatafala | HRC58 – HRC63 | Bokhoni ba Tlhahiso | Ho feta lithane tse 30000 ka selemo |

| Mofuta oa Ts'ebetso | Ho lahla | Phekolo ea Bokaholimo | Ho penta/ Ho fafatsa-Pente |

| Tlhahlobo ea Tlhahiso | Teko ea boima, tlhahlobo ea metallographic, tlhahlobo ea spectral, thepa ea mochini le kalafo ea mocheso. | ||

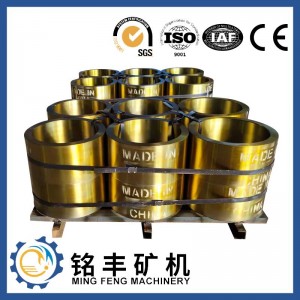

| Sephutheloana sa Lipalangoang | E phuthetsoe ka Pallet/Case | Tiisetso | E ts'oanang le ea mantlha |

| Boleng | Boemo bo Phahameng | Phihlelo | Ho feta lilemo tse 30 |

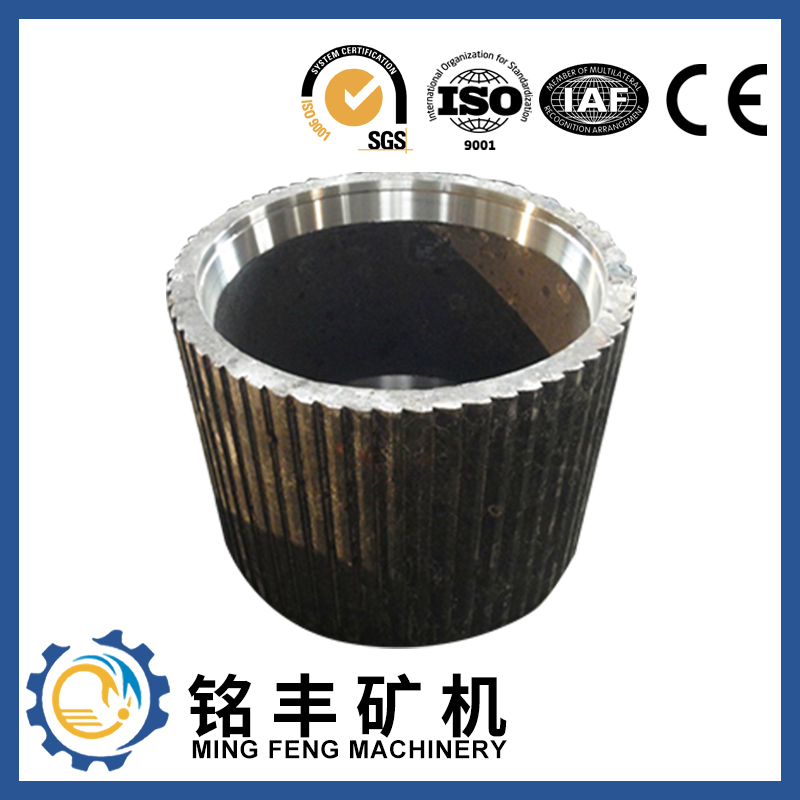

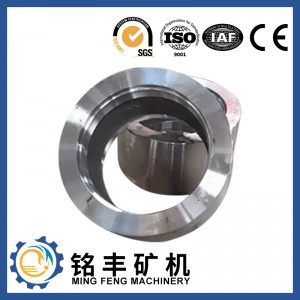

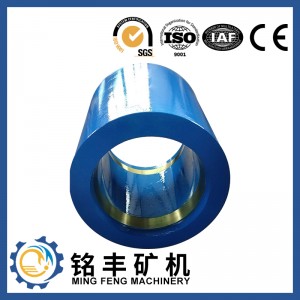

Letlalo le phahameng la chromium komporo

Letlalo le joalo la kantle le entsoeng ka alloy e phahameng ea chromium, lesela la tšepe le ductile, boima bo phahameng ba holim'a metsi, le sebelisoa haholo bakeng sa mochini o silakanyang o sebelisoang ka lithaelese tsa ceramic scission, gangue ea mashala, shale, lits'ebetso tsa indasteri ea litene li hlahloba hantle ha o ntse o kopanya ho kopanya tse tala. thepa, ho eketseha formability, le thepa e ka tlaase e tala ea polasetiki kapa letsopa sekoti litene phahameng porosity hlokahala thepa e tala bakeng sa tshebetso e ntle dikopo.Khetha sesebelisoa se lokela ho hlomelloa ka lesale la grinder ho netefatsa ts'ebetso e nepahetseng le ho bapala karolo ea eona.

Litšobotsi tsa High chromium cast iron roller ka centrifugal casting.

1. Ho sebelisa theknoloji ea bi-metal composite centrifugal casting.

2. The centrifugal casting ntle le pores le inclusions ka ho sebelisa matla a centrifugal.

3. Ho potlaka ha tšepe hlobo ea tšepe e etsang hore ho lahla ho be le microstructure e kopanetsoeng ho ntlafatsa ho hanyetsa ho apara.

4. Ho sebelisa tšepe e phahameng ea chromium (Cr17NiMo, Cr18Ni2, joalo-joalo) ho ea ka ntle ho lera la rolara, ho sebelisa tšepe ea alloy ductile joaloka GGG400 joalo-joalo kapa tšepe ea alloy joaloka 35CrNiMo joalo-joalo ka lera le ka hare (ka matla a phahameng le boima).

5. Ka mokhoa o utloahalang oa ho roala botenya, ho latela tlhokahalo ea bareki ho fokotsa litekanyetso tsa alloy le litšenyehelo.

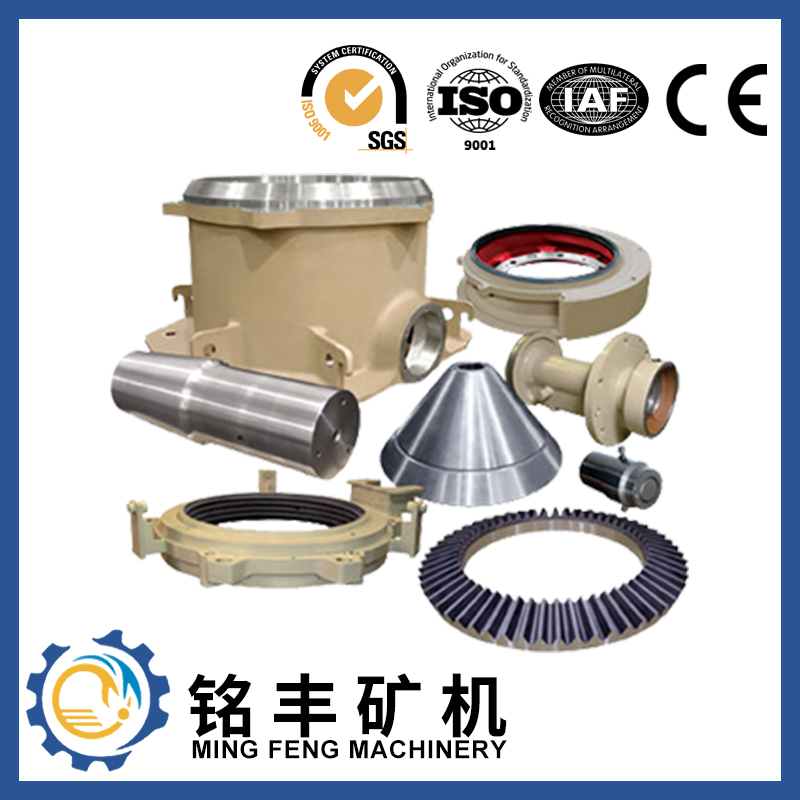

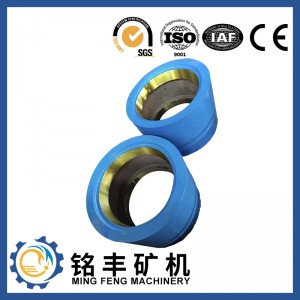

Likarolo tsa Crusher:

Re na le likarolo tse ling tse kentsoeng ka mokhoa o nepahetseng ho kenyelletsa hlooho, likotlolo, shaft e kholo, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner le tse ling, re ka tšehetsa mochine oa hau kaofela likarolo tsa lisebelisoa tsa mochini.

Ha u na mohlala oo u o hlokang?

Ha u na mohlala oo u o hlokang?

Re sebetsa ka litšoantšo tsa tekheniki bakeng sa lihlahisoa leha e le life tse sa tloaelehang.Haeba odara e le ea likarolo tse tloaelehileng, o tlameha feela ho re fa nomoro ea karolo e le hore re ka hlalosa likarolo tsa odara.

TLHOKOMELO E TLOANG

Boleng ba Pele, Tšireletseho e Tiisitsoe