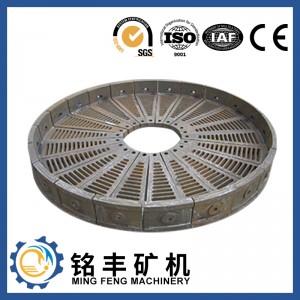

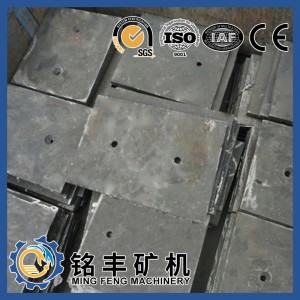

Ball mill liner plate

Kakaretso:

| Mofuta | Boto ea li-crusher, poleiti ea lesela | ||

| Tšimoloho | China | Khoutu ea HS | 84749000 |

| Boemo | E ncha | Ho sila ores | Quartz, Gold ore, Cement clinker, joalo-joalo. |

| Mofuta oa Mochini | Ball Mill Liner | Setifikeiti | ISO 9001:2008 |

| Lisebelisoa tse ka Sehloohong | Mn13Cr2 , Mn18Cr2, Mn22Cr2, Cr22, Cr26 | ||

| Mofuta oa Ts'ebetso | Ho lahla | Phekolo ea Bokaholimo | Ho penta/ Ho fafatsa-Pente |

| Tlhahlobo ea ho Lahlela | Sesebelisoa sa Spectrum se bala ka kotloloho, Tlhahlobo ea Metallographic, Tlhahlobo ea Ultrasonic, Tlhahlobo ea Karolo ea Magnetic, Tlhahlobo ea Thepa ea Mechini. | ||

| Sephutheloana sa Lipalangoang | E phuthetsoe ka Pallet/Case | Tiisetso | E ts'oanang le ea mantlha |

| Boleng | Boemo bo Phahameng | Phihlelo | Ho feta lilemo tse 30 |

Tlhaloso:

Mosebetsi o ka sehloohong oa li-ball mill liner ke ho sireletsa karolo e kholo ea leloala ntle le abrasion, tlhokahalo ea bohlokoa ka ho fetisisa bakeng sa thepa ke tšobotsi ea ho hanyetsa ho apara hantle le boima bo phahameng.Thepa e phahameng ea manganese e nang le boima bo lekaneng, 'me e tla ba e thata-thata ka tšusumetso e itseng, e tla etsa hore thepa e be betere holim'a boima le ho se mamelle, kahoo e sebelisoa e le thepa e sebelisoang haholo bakeng sa liner.

Re ka etsa mefuta eohle ea likarolo tsa li-crusher ho latela litlhoko le litšoantšo tsa bareki.Haeba u thahasella lihlahisoa tsa rona 'me u batla ho tseba tlhahisoleseding e tsoang ho rona ka kōpo ikutloe u lokolohile ho ikopanya le rona

Litlhaloso tsa sehlahisoa

| Lisebelisoa | Sebaka sa kopo | Bophelo ba tšebeletso | Ho thatafala | Matla a amang (J/cm²) |

| Aene ea Cast Aene e phahameng ea chromium | ≤Φ5m mill liner, separator liner, joalo-joalo | ≥7 Lilemo | HRC≥60 | 8-10 |

| High-chromium Cast IronI (Cr 18MoNiCuV) | ≤Φ5m mill liner, Liner tse otlolohileng, joalo-joalo | ≥6 Lilemo | HRC≥60 | 7-9 |

| High-chromium Cast IronI (Cr 15MoNiCuV) | ≤Φ4.2m mill liner, separator liner, joalo-joalo | ≥5 Lilemo | HRC≥58 | 6-8 |

| High-chromium Cast IronI (Cr 12MoNiCuV) | ≤Φ4.2m mill liner, ka thoko-liner, phanele ea karohano, joalo-joalo | ≥4 Lilemo | HRC≥55 | 6-9 |

| Cr-Mo-Ni Alloy Steel | ≤Φ5m mill liner, ka thoko-liner, phanele ea karohano. Grateplate;poleiti ea ho senya. poleiti ea grate.etc | ≥4 Lilemo | HRC≥52 | ≥40 |

| Medium-carbon Multicomponent Alloy Steel | ≥3 Lilemo | HRC≥50 | ≥30 | |

| Chrome e bohareng Alloy Steel | ≥2 Lilemo | HRC≥48 | ≥20 | |

| Tšepe ea Alloy e tlase | ≥1.5 Lilemo | HRC≥45 | ≥40 | |

| Phaello e tlase ea Carbon Alloy Steel | Mohala oa ka oa leloala o metsi.ka thoko-liner. poleiti ea grid.joalo-joalo. e kholo ea boholo bo boholo e tala mater ial mill drying chamber blind plate.etc | ≥1 Lilemo ≥3 Lilemo | HRC≥46 | ≥50 |

| Tšepe e Phahameng ea Manganese(Mn13) | Mohala oa ka oa leloala o metsi.ka thoko-liner.grid plate.etc. | ≥8 Likhoeli | HRC≥200 | ≥147 |

| Alloyed High Manganese Steel(Mn13Cr2) | Sekhahla sa ho senya.poleiti ea grate.etc. sefate sa mohlahare sa mohlahare | ≥7 Lilemo | HRC≥220 | ≥120 |

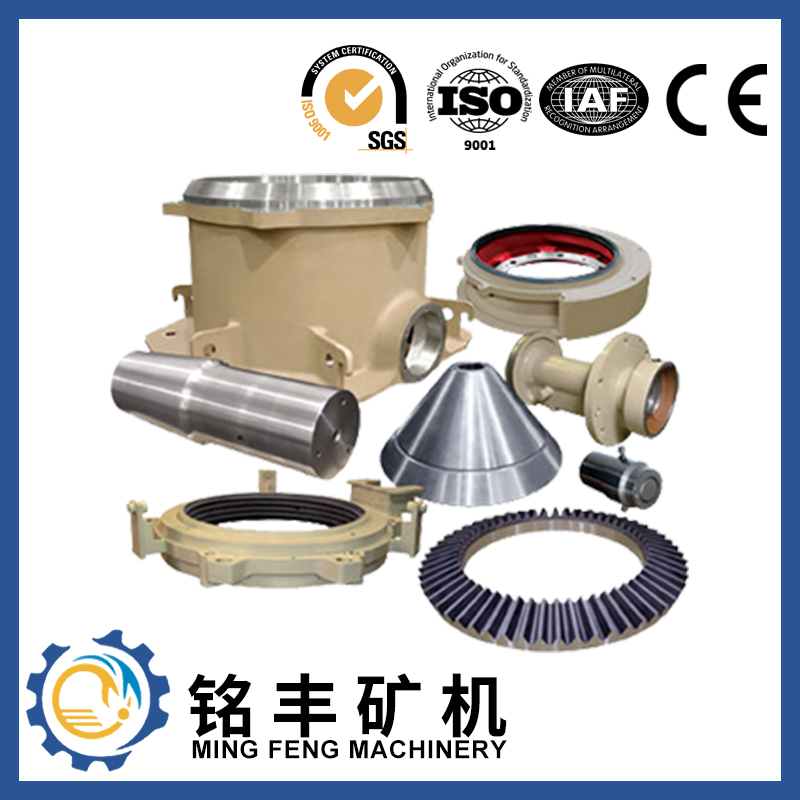

Likarolo tsa Crusher:

Re na le likarolo tse ling tse kentsoeng ka mokhoa o nepahetseng ho kenyelletsa hlooho, likotlolo, shaft e kholo, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner le tse ling, re ka tšehetsa mochine oa hau kaofela likarolo tsa lisebelisoa tsa mochini.

Ke hobane'ng ha u re khetha?

Lilemo tse 1.30 tsa boiphihlelo ba tlhahiso, lilemo tse 6 tsa boiphihlelo ba khoebo ea kantle ho naha

2.Strict boleng taolo, Own laboratori

3.ISO9001:2008, BUREAU VERITAS

TLHOKOMELO E TLOANG

Boleng ba Pele, Tšireletseho e Tiisitsoe