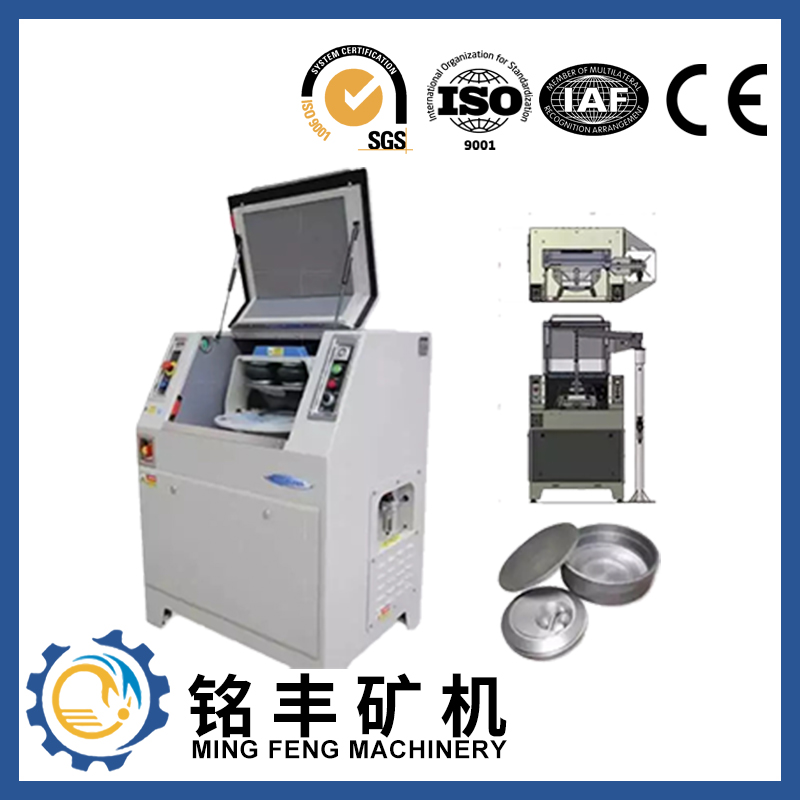

Sekotlolo sa ho sila bolo bakeng sa lab

Tlhaloso:

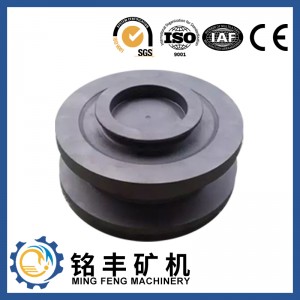

Tungsten carbide pulverising leloala sekotlolo se na le boima bo phahameng, ho hanyetsa ho roala, matla a matle le ho tiea, ho hanyetsa mocheso, ho hanyetsa kutu le letoto la thepa e babatsehang, haholo-holo boima ba eona bo phahameng le ho apara ho hanyetsa, esita le tlas'a mocheso oa 500 ℃ ke motheo o ntse o tšoana; ka 1000 ℃ e ntse e na le boima bo phahameng.

E sebelisoa haholo sesole-liindasteri rarahaneng, lifofane, mechine, metallurgy, ho cheka oli, lisebelisoa tsa meepo, puisano ea elektronike, kaho le masimo a mang, hammoho le ntshetsopele ya liindasteri tlaase noka, carbide eketseha tlhokahalo ea mmaraka.'Me bokamoso ba libetsa le thepa ea thepa e ncha le e phahameng, tsoelo-pele ea morao-rao ea saense le theknoloji le tsoelo-pele e potlakileng ea matla a nyutlelie, e tla ntlafatsa botsitso ba litaba tsa theknoloji e phahameng le boleng bo phahameng ba tlhokahalo ea lihlahisoa tse thata tsa alloy.

Melemo:

1. boleng bo phahameng bo tsoelang pele

2. ka matsatsi a 30 nako ea ho fana ka tlhahiso ea batch

3. tšebeletso e ntle pele le ka mor'a tlhahiso

4. taolo e tiileng mabapi le ho fumana thepa e tala le ka mor'a tlhahlobo ea tlhahiso

Seteishene sa sekotlolo sa ho sila sa Leloala la Pulverizer:

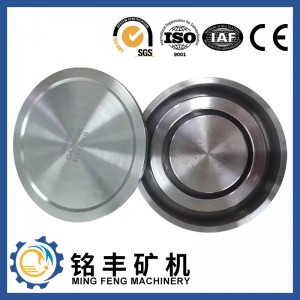

Seteishene sa ho sila sa leloala la laboratori ea Pulverizer se entsoe ka tšepe ea tšepe 65Mn kapa Cr12, karolo e ka etsoa ka tšepe ea tšepe, tšepe e bohlooho, tšepe ea ductile le eona, e sebelisoa bakeng sa sampole ea laboratori.

Likarolo tsa tšepe le likarolo tsa tšepe tse tsoang fekthering ea ka li rekisitsoe linaheng tse 'maloa tse fapaneng,' me li fumane mokitlane o motle ho tsoa ho bareki ka tšebeletso ea boleng bo holimo le e nahanelang.

Ka kopo ikopanye le rona ka tlhoko ea hau e khethehileng:

1.Kereiti le boholo bo itseng kapa setšoantšo

2.Bongata le boleng.

3. Tikoloho ea ts'ebetso,

4.Tlhoko e 'ngoe e khethehileng.

TLHOKOMELO E TLOANG

Boleng ba Pele, Tšireletseho e Tiisitsoe